- BendPak

- >

- BendPak HDS-40X 40,000-lb. Capacity / Four-Post Lift / Extended

BendPak HDS-40X 40,000-lb. Capacity / Four-Post Lift / Extended

BendPak's HDS-Truck Series four-post lifts are a whole new breed of rugged. They're newly engineered super-duty truck lifts that make light work out of heavy lifting. They work better, are built to last, and feature upgrades that increase safety, durability and productivity. Four models provide a generous 35,000 or 40,000-lb. lifting capacity and feature extra-wide runways to accommodate a wide variety of vehicle configurations.

The HDS-40X is BendPak's heaviest-duty, extended-length truck lift. That makes it the most powerful offering in our arsenal. A rugged design with safety features unmatched in the industry, anyone working on massive commercial vehicles should consider this mighty machine.

BendPak's Strongest and Longest Beast of Burden

40,000 lbs. take a lot of muscle to lift, and many vehicles of this caliber are longer than our standard-length series of four-post lifts can accommodate. If you want to be prepared for the longest and heaviest vehicles on the road, you need BendPak's most impressive offering—and this is undoubtedly it. With runways that measure in at a whopping 323”, the HDS40X is the heaviest-duty extended-length car lift we make. Slap a bus on it and get to work, no sweat.

The power of this lift is no light matter. Military contractors, government entities on all levels and large commercial truck repair companies have all sought this lift out, knowing there's nothing they can throw at it that it can't handle. Far from being a hobby lift, this industrial-grade powerhouse is only going to fit in serious-minded commercial maintenance spaces. You'll need a big bay with high ceilings, and if you have that, the HDS-40X doubles as a parking lift and ultra-safe storage space.

Super-long runways

Super-duty vehicles need a clean approach and a wide runway to safely board a lift. At 28" wide, these runways accommodate tires of virtually any diameter and width. The non-skid surface is sure to grip tires and hold them in place, even if they get wet or oily during your work.

Dual-hub cable sheaves

BendPak cable sheaves are made to dominate every lifting application, however big or small. 12" diameter sheave bodies and 4" axles make them far more likely to last the lifespan of your lift because of their sheer size and quality of construction.

Large base plates

Truck lift base plates are made super-wide, which makes sense considering the size of the vehicles you're putting on the runways. 12 x 12 plate dimensions are extremely secure for maximum stability and lifting longevity.

Spring-loaded safety locks

13 lock positions offer up to 60" of rise for comfortable undercarriage access. All locks automatically engage during rise and disengage at the touch of a button. Just one look at the lock sizes will inspire confidence that this lift is safer than any you've ever seen.

Secondary lock system

The primary locks are more than enough security, but we don't leave a single, tiny thing to chance. So, we include a backup cable-slack detection system that captures loose cables immediately if slack develops. This system makes it entirely safe to remedy any issues without risking uneven platforms.

Rolling bridge jacks

Need to perform wheel service on your fleet? Of course you do. Pick up a pair of RBJ25000 bridge jacks and start working. Together, two jacks will lift a vehicle up to 50,000 lbs., but keep in mind the HDS14X has a 40,000-lb. limit. The extra 10K is not just peace-of-mind, but a practical consideration since the front half of most trucks (where the engine and transmission rest) is likely to be heavier than the back.

Features

- 40,000-lb. lifting capacity

- Supersized 12" diameter cable sheaves

- Stainless steel lifting cables

- Extended length runways

- Grease nipples

- Single hydraulic under-runway cylinder

- Integrated flow restrictor

- Durable powder coat

- Spring-loaded safety locks

- Second lock system on constant guard

- Fully enclosed lifting cables

- Multiple adjustable height locking positions

- Maintenance-free electric hydraulic power system

- Conveniently positioned operator controls

- 12" x 12" base plates

- Non-skid runways

- Optional rolling jacks

HDS-40X Specifications

Capacity

Lifting Capacity*40,000 lbs. (18,144 kg)

*Max Capacity / Front Axle20,000 lbs. (9,072 kg)

*Max Capacity / Rear Axle20,000 lbs. (9,072 kg)Rise

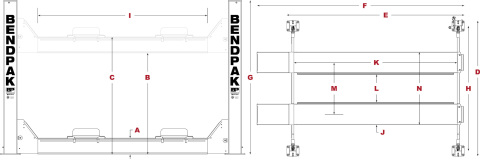

A - Min. Runway Height:8.5" (216 mm)

B - Max. Rise:60" (1,524 mm)

C - Max. Lifting Height:68.5" (1,740 mm)

Time to Full Rise:75 secondsOutside Dimensions

D - Overall Width:154" (3,912 mm)

E - Outside Length:317" (8,052 mm)

F - Overall Length:357" (9,068 mm)

G - Height of Columns:93" (2,362 mm)Inside Dimensions

H - Width Between Columns:134" (3,404 mm)

I - Drive-Thru Clearance:109" (2,769 mm)Runways

J - Runway Width:28" (711 mm)

K - Length of Runways:323" (8,204 mm)

L - Width Between Runways:36" (914 mm) or 47" (1,194 mm)

M - Runway Centerline:64" (1,626 mm) or 75" (1,905 mm)

N - Outside Edge of Runways:92" (2,337 mm) or 103" (2,616 mm)Minimum Wheelbase

Rated Capacity:230" (5,842 mm)

75% Capacity:195" (4,953 mm)

50% Capacity:165" (4,191 mm)

25% Capacity:130" (3,302 mm)

Locking

Locking Positions: 9

Lock Spacing:Every 6" (152 mm)

Power Unit

Motor:220 VAC / 60 Hz / 1 Ph

Noise:45 dB

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201.

-

Description

-

Features and Specs

Spring-loaded safety locks automatically engage continuously during rise and adjustable safety ladders allow for precise runway leveling even when installed on sloped floors.

Supersized 12” diameter cable sheaves within the runway and cross tubes combined with massive 4” diameter sheave axles dramatically improve cable wear and critical component lifespan meaning you’ll increase safety and spend less money in service related expenses down the road.

BendPak's HDS-Truck Series lifts feature four stainless-steel lifting cables that provide a great balance between abrasion resistance and fatigue.

Grease nipples are located on every sheave and sheave axle to make lubrication maintenance a breeze.

Each HDS-Truck Series four-post lift is equipped with a single hydraulic cylinder hidden away under the runway for maximum performance and reliability and minimum exposure to elements. The hydraulic cylinder features high-durometer rod seals, pressure loaded U-cup piston seals, backups and wear bands that virtually eliminate any fluid bypass. The welded cylinder body is made from high strength steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures straight, smooth, cylinders that will provide years and years of dependable trouble-free service. Leak proof cylinder technology only available for BendPak four-post lifts

An integrated hydraulic flow restrictor provides a controlled descent in the unlikely event of an unexpected hose rupture.

A durable powder coat finish can withstand harsh environments and chemical spills and will provide years of protection.

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders will provide years of trouble-free service.

A secondary lock system is on constant guard and acts as a slack-cable device in the unlikely event of an unexpected cable failure.

Lifting cables, airlines, safety latches and sheaves are all fully enclosed within lift structure.

Features multiple adjustable height locking positions for variable-height parking and infinite leveling.

A maintenance-free electric hydraulic power system assures ultimate dependability.

All operator controls are conveniently located within easy reach.

12" x 12" base plates provide a solid foundation.

Non-skid runways provides maximum grip, even when the runway surface is wet or oily.

Optional rolling jacks make a great addition to increase service capacity. Rolling jacks are used to raise the front or rear portion of a vehicle off the runways allowing operators to perform efficient wheel and brake service. A pair of jacks allows the entire vehicle to be elevated. Each jack has telescoping arms and frame contact pads that can be extended over the runways and positioned under vehicle lifting points. Each jack features three safety-lock positions and stackable truck and van adapters for increased lifting height and better access to frame contact points on high ground-clearance vehicles. The jacks come equipped with a commercial grade air-hydraulic pump.

Supersized 12" diameter cable sheaves

Stainless steal lifting cables

Extended length runways

Grease nipples

Single hydraulic under-runway cylinder

Integrated flow restrictor

Durable powder coat

Spring-loaded safety locks

Second lock system on constant guard

Fully enclosed lifting cables

Multiple adjustable height locking positions

Maintenance-free electric hydraulic power system

Conveniently positioned operator controls

12" x 12" base plates

Non-skid runways

Optional rolling jacks

*Max capacity / front axle: 20,000 lbs. / 9,072 kg

*Max capacity / rear axle: 20,000 lbs. / 9,072 kg

Overall width: 154" / 3,912 mm

Outside length: 317" / 8,052 mm

Overall length: 357" / 9,068 mm

Height of columns: 93" / 2,362 mm

Runway min height: 8-1/2" / 216 mm

Max rise: 60" / 1,524 mm

Max lifting height: 68-1/2" / 1,740 mm

Width between posts: 134" / 3,404 mm

Runway width: 28" / 711 mm

Width between runways: 36" – 47" / 914 mm – 1,194 mm

Runway centerline: 64" - 75" / 1,625 mm to 1,905 mm

Outside edge of runways: 92" - 103" / 2,367 mm - 2,616 mm

Drive-thru clearance: 109" / 2,769 mm

Length of runways: 323" / 8,204 mm

Min wheelbase @ rated capacity: 230" / 5,842 mm

Min wheelbase @ 75% capacity: 195" / 4,953 mm

Min wheelbase @ 50% capacity: 165" / 4,191 mm

Min wheelbase @ 25% capacity: 130" / 3,302 mm

Locking positions: 9

Lock spacing: every 6" / 152 mm

Lifting time: 75 sec

Motor: 220 VAC / 60 Hz / 1 Ph