- BendPak

- >

- BendPak HDS-27 Heavy Duty 4 Post Car Lift 27,000 lb. - New Gray

BendPak HDS-27 Heavy Duty 4 Post Car Lift 27,000 lb. - New Gray

If you need a bigger, better four-post lift that can handle a 27,000-lb., Class 7 semi-truck, you need the HDS-27. Bigger sheaves and beefier components carry on our legacy of dependability. If your shop services commercial and/or municipal vehicles, this lift is practically mandatory.

Construction, Municipal and Commercial Vehicles Welcome

This is where our car lifts really step into the next level of lifting. While the HDS-18E is an entry-level lift in the medium-duty truck category, the HDS-27 is well-suited to take your business well beyond the needs of most private drivers. This garage lift brings you into the realm of construction equipment, commercial flatbed trucks, concrete mixers, garbage trucks, buses, etc.

Every BendPak four-post lift, regardless of lift capacity, is made to exacting standards and gets the job done without undue strain or pain on the equipment. When we rate a truck lift at 27,000 lbs., that means anything at or under that weight limit is a cinch for our lifts to handle. We superbly over-engineer everything, so you can keep the “biggest and baddest” commercial and municipal vehicles up to code and ready for the next great haul.

Extended runways

Longer runways accommodate a wide variety of vehicle wheelbases, allowing you to steer massive trucks and buses onto our ramps without damaging your vehicle chassis.

Dual-hub cable sheaves

We take the time, cost and effort to bring you the best. Each sheave contained within the runway and cross tubes is a massive 12” in diameter, and the sheave axles, at 4” in diameter, greatly extend the lifespan of your lift by reducing the overall wear put on these parts. Manufacturing sheave components are even bigger than ones offered by our competition, which ensures superior quality in our product. Additionally, BendPak parts always meet or exceed ALI standards for load bearing and safety.

Heavy-duty aircraft cable

Each of the four, 1/2” diameter, 6 x 25 stainless-steel lifting cables has a 14,000-lb. breaking strength, so a four-post lift as massive as this has the engineering to keep your vehicles safe at all times, especially during periods of heavy use. They won’t rust out or break apart due to bad weather, chemicals or random, floating garage particulate.

Built-in lubrication

The sheaves and sheave axles are fitted with grease nipples to lubricate the parts as they move. This is an essential feature that is also a form of auto-maintenance, so you have little to do during your periodic service checks.

Flow restrictor

This truck lift provides the best that modern hydraulic technology has to offer. Integrated into the hydraulic cylinder is a flow restrictor that provides a safe, slow descent. This is true even in the extremely rare occurrence of a burst or ruptured hydraulic hose.

Large base plates

Substantial 12" x 12" base plates support the massive columns.

Spring-loaded safety locks

When the HDS-27 truck lift rises, spring-loaded safety locks engage the moving platforms. Safety ladders are standard and can be adjusted to keep the runways level, which is especially useful for sloped floors.

Push-button pneumatic lock release

The steel and aluminum pneumatic cylinders are aircraft-quality and certified to last for years without service. Lowering the lift release off the locks is done with one push against the pneumatic lock release. Just another simple way we put you in total control of your lift operations.

Secondary lock system

Two locks are better than one! A secondary slack-cable lock engages in case of cable failure, which is unlikely to occur. Still, we prepare our heavy-duty lifts for the worst to keep you working at your best.

Integrated design

Tucked safely into the structure of the four-post lift columns, our lifting cables, airlines, safety latches and cable sheaves are kept away from inclement weather, hazardous chemical erosion and garage dirt/debris. The column structure is the safest and most logical place to conceal the working parts of the lift. Internally routed parts are also crucial to creating the beautiful BendPak aesthetic our customers have come to know and love!

Adjustable height locking positions

Four-post lifts accommodate many different vehicle types, so we’ve made sure you can adjust the height to suit your needs and safely lock your vehicle in place.

Electric-hydraulic power system

Our car lifts are designed with all operator buttons within reach, so you can raise, lower or shut down the system at any time. One-push button controls make the whole process that much smoother.

Non-skid runways

Runways should be built to hold vehicles steady in case of oil spills or wet surface conditions. Even in bad weather, the non-skid runways on this four-post lift are tough, textured and rugged to the touch.

Flexible protective conduit

All of BendPak’s heavy-duty cables are fitted with a protective casing that is flexible and non-conducive to electricity. Your hoses will be intact and serviceable for many years without service, and the non-metallic tubing will ensure you’re never shocked by anything other than the great value of your purchase.

Rolling bridge jacks

Bridge jacks raise the wheels above the runways, which lets operators perform wheel and brake service on the car. Since the HDS-27 Series supports some extremely heavy vehicles, the truck and SUV adapter set is a necessity for wheel/brake service on these lifts. Commercial-grade hydraulic pumps come standard and require 125 PSI and 10 – 20 CFM.

Choose extended length

Some vehicles at the 27,000-lb. lift capacity begin to develop monstrous proportions. Garage trucks, for instance, are wide, tall and feature wide wheel bases. You need a car lift that can handle all those dimensions, plus the weight, without crapping out on you. The super-long HDS-27X may be the better option for your shop. Just be sure to discuss your service needs with a trained BendPak service representative if you need help deciding which 27K four-post lift is right for you.

*Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2011 or ANSI/UL 201. Consult www.autolift.org for a complete list or contact BendPak via contact@bendpak.com.

Features

- 27,000-lb. lifting capacity

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN 1493

- Supersized 12" diameter cable sheaves

- Stainless steel lifting cables

- Grease nipples

- Single hydraulic under-runway cylinder

- Integrated flow restrictor

- Durable powder coat

- Spring-loaded safety locks

- Second lock system on constant guard

- Fully enclosed lifting cables

- Multiple adjustable height locking positions

- Maintenance-free electric hydraulic power system

- Conveniently positioned operator controls

- 12" x 12" base plates

- Non-skid runways

- Optional rolling jack

Capacity

Lifting Capacity* 27,000 lbs. (12,247 kg)

*Max Capacity / Front Axle 13,500 lbs. (6,123 kg)

*Max Capacity / Rear Axle13,500 lbs. (6,123 kg)

Rise

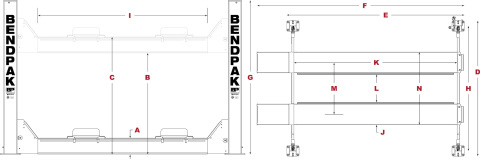

A - Min. Runway Height: 83.5" (2,121 mm)

B - Max. Rise: 60" (1,524 mm)

C - Max. Lifting Height: 68.5" (1,740 mm)

Time to Full Rise:75 seconds

Outside Dimensions

D - Overall Width: 154" (3,912 mm)

E - Outside Length: 257" (6,528 mm)

F - Overall Length: 297" (7,544 mm)

G - Height of Columns: 93" (2,362 mm)

Inside Dimensions

H - Width Between Columns: 134" (3,404 mm)

I - Drive-Thru Clearance: 109" (2,769 mm)

Runways

J - Runway Width: 22" (559 mm)

K - Length of Runways: 263" (6,680 mm)

L - Width Between Runways: 38" (965 mm) or 56" (1,422 mm)

M - Runway Centerline:60" (1,524 mm) or 78" (1,981 mm)

N - Outside Edge of Runways: 82" (2,083 mm) or 100" (2,540 mm)

Minimum Wheelbase

Rated Capacity: 185" (4,699 mm)

75% Capacity: 160" (4,064 mm)

50% Capacity: 135" (3,429 mm)

25% Capacity: 110" (2,794 mm)

Locking

Locking Positions: 9

Lock Spacing: Every 6" / 152 mm

Power Unit

Motor: 220 VAC / 60 Hz. 1Ph.

Noise: 45 dB

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201.

-

Description

-

Features and Specs

Looking for even more lifting capabilities? Check out the the extended HDS-27X.

All HDS-27 standard length truck lifts feature:

Supersized 12” diameter cable sheaves within the runway and cross tubes combined with massive 4” diameter sheave axles dramatically improve cable wear and critical component lifespan meaning you’ll increase safety and spend less money in service related expenses down the road.

BendPak's HDS-Truck Series lifts feature four stainless-steel lifting cables that provide a great balance between abrasion resistance and fatigue.

Grease nipples are located on every sheave and sheave axle to make lubrication maintenance a breeze.

Each HDS-Truck Series four-post lift is equipped with a single hydraulic cylinder hidden away under the runway for maximum performance and reliability and minimum exposure to elements. The hydraulic cylinder features high-durometer rod seals, pressure loaded U-cup piston seals, backups and wear bands that virtually eliminate any fluid bypass. The welded cylinder body is made from high strength steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures straight, smooth, cylinders that will provide years and years of dependable trouble-free service.Leak proof cylinder technology only available for BendPak four-post lifts

An integrated hydraulic flow restrictor provides a controlled descent in the unlikely event of an unexpected hose rupture.

A durable powder coat finish can withstand harsh environments and chemical spills and will provide years of protection.

Spring-loaded safety locks automatically engage continuously during rise and adjustable safety ladders allow for precise runway leveling even when installed on sloped floors.

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders will provide years of trouble-free service.

A secondary lock system is on constant guard and acts as a slack-cable device in the unlikely event of an unexpected cable failure.

Lifting cables, airlines, safety latches and sheaves are all fully enclosed within lift structure.

Features multiple adjustable height locking positions for variable-height parking and infinite leveling.

A maintenance-free electric hydraulic power system assures ultimate dependability.

All operator controls are conveniently located within easy reach.

12" x 12" base plates provide a solid foundation.

Non-skid runways provides maximum grip, even when the runway surface is wet or oily.

Optional rolling jacks make a great addition to increase service capacity. Rolling jacks are used to raise the front or rear portion of a vehicle off the runways allowing operators to perform efficient wheel and break service. A pair of jacks allows the entire vehicle to elevated. Each jack has telescoping arms and frame contact pads that can be extended over the runways and positioned under vehicle lifting points. Each jack features three safety-lock positions and stackable truck and van adapters for increased lifting height and better access to frame contact points on high ground-clearance vehicles. The jacks come equipped with a commercial grade air-hydraulic pump.

CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN 1493

Supersized 12" diameter cable sheaves

Stainless steal lifting cables

Grease nipples

Single hydraulic under-runway cylinder

Integrated flow restrictor

Durable powder coat

Spring-loaded safety locks

Second lock system on constant guard

Fully enclosed lifting cables

Multiple adjustable height locking positions

Maintenance-free electric hydraulic power system

Conveniently positioned operator controls

12" x 12" base plates

Non-skid runways

Optional rolling jacks

*Max capacity / front axle: 13,500 lbs. / 6,124 kg

*Max capacity / rear axle: 13,500 lbs. / 6,124 kg

Overall width: 154" / 3,912 mm

Outside length: 257" / 6,528 mm

Overall length: 297" / 7,544 mm

Height of columns: 93" / 2,362 mm

Runway min height: 8-1/2" / 216 mm

Max rise: 60" / 1,524 mm

Max lifting height: 68-1/2" / 1,740 mm

Width between posts: 134" / 3,404 mm

Runway width: 22" / 559 mm

Width between runways: 38" – 56" / 965 mm – 1,422 mm

Runway centerline: 60" - 78" / 1,524 mm to 1,981 mm

Outside edge of runways: 82" - 100" / 2,083 mm - 2,540 mm

Drive-thru clearance: 109" / 2,769 mm

Length of runways: 263" / 6,680 mm

Min wheelbase @ rated capacity: 185" / 4,699 mm

Min wheelbase @ 75% capacity: 160" / 4,064 mm

Min wheelbase @ 50% capacity: 135" / 3,429 mm

Min wheelbase @ 25% capacity: 110" / 2,794 mm

Locking positions: 9

Lock spacing: every 6" / 152 mm

Lifting time: 75 sec

Motor: 220 VAC / 60 Hz / 1 Ph

Shipping weight: 5,581 lbs. / 2,537 kg

Shipping dimensions: 270" x 23" x 36" / 6,858 mm x 584 mm x 914 mm