- BendPak

- >

- BendPak,HDS-40 40,000-lb. Capacity / Four-Post Lift / Standard

BendPak,HDS-40 40,000-lb. Capacity / Four-Post Lift / Standard

The HDS-40 four-post lift is the safest, beefiest, biggest, baddest, meanest and every other “-est” word for a truck lift we can use to mean, “It doesn’t get better than this.” This extreme heavy-duty four-post lift can support the weight of a Greyhound™ bus, as well as a mobile home or RV.

The Only Heavy-Duty Car Lift You’ll Ever Need

An HDS40 four-post lift lets you wrench on absolutely massive vehicles. Nothing in BendPak’s lineup has this much brute force to accompany the same features found on our other heavy-duty lifts. That means the ergonomic controls, massive sheaves, over-engineered lift components and aircraft-quality cables are all here to guarantee the ultimate lifting experience.

Extended runways

Car lifts with longer runways are less prone to causing accidental vehicle damage. For our largest four-post lift, we make sure the most massive 40K trucks and commercial vehicles can safely make their way onto the ramps for service.

Dual-hub cable sheaves

Truck lift sheaves are made 12” in diameter with 4” diameter sheave axles and are necessarily over-engineered for safer lifting. They’re low-maintenance and low-cost for the entire lifespan of your lift. All four sheaves rotate in perfect synchronization to achieve a smooth, even lift, 100% of the time.

Heavy-duty aircraft cable

BendPak’s heavy-duty, 1/2” diameter, 6 x 25 stainless-steel lifting cables are expertly engineered to withstand the weights of fully loaded full-size flatbeds and city buses. The cables are completely resistant to rust and chemical reactions, as well as environmental factors such as heat, humidity, air particulate, etc. And since this is a BendPak cable we’re talking about, it requires very little maintenance over time.

Built-in lubrication

To keep your cables sliding gently through the sheaves, self-lubricating grease nipples are fitted through the sheave and sheave axle for many years of optimum performance. We keep the grease where it belongs: along the sheave, not on your floor.

Flow restrictor

A flow restrictor is built in to the hydraulic cylinder, providing a safe descent in the rare (and very unlikely) event of a catastrophic hose rupture. Even in the worst-case scenario, your truck lift will gently descend and safely touch down on the ground. Chances are you’ll never have to see this feature at work, but we engineered it just in case.

Large base plates

Truck lift base plates are made a little wider than the bases of our lighter-duty models: 12 x 12 plate dimensions are sturdy and can be easily bolted into suitable concrete flooring for years of extreme security. No wobbles, no worries.

Spring-loaded safety locks

As the lift ascends, adjustable safety locks audibly click into place at multiple levels. This lets you choose your preferred service lifting point and accommodate for uneven floors. 13 lock positions make for an incredibly safe and versatile four-post lift.

Push-button pneumatic lock release

A one-push pneumatic release simultaneously disengages all four locks for a rapid descent that never loses its balance. Stainless steel and aluminum pneumatic cylinders are aircraft-quality, tested and overloaded right here in our own California facilities to ensure optimum functionality and soundness of design. Our quality control experts always listen for a smooth hiss that accompanies the release and descent of every healthy lift we manufacture.

Secondary lock system

A cable-slack detection device acts as a secondary lock in case of a mechanical failure on the lift. Mechanical failures on any BendPak four-post lift are uncommon but more likely to occur than hydraulic failures, given the nature and operation of moving parts. Other lift companies do not incorporate slack-cable detection and thereby put your lift at risk; if one of your posts experiences cable slack, imagine the catastrophe that would follow if it continued to descend unevenly. We don’t like to think about it, so we eliminated the concern: in case of any cable slack, a BendPak lift shuts down completely, keeping you, your lift and your vehicle safe until the problem can be resolved.

Integrated design

All components on this four-post lift are internally routed within the structure: cables, sheaves, axles, etc. Even the hydraulic cylinder is hidden underneath the lift. This ensures a cleaner product that’s well-suited for side-by-side stacking—no cumbersome components to knock into each other when multiple units are installed. It also makes for a better-looking lift. Not to mention, cables and sheaves perform better when they aren’t exposed to dirt, grime and other shop conditions that might affect performance.

Adjustable height locking positions

13 locking positions mean you have more versatility with where you position the ramps. Most other companies only provide 10 positions on their four-post lift models. It might sound minor, but we knows inches make a big difference when it comes to operator comfort.

Electric-hydraulic power system

A lift is only as good as the hydraulic power unit that keeps it running. With ergonomic one-push button control, a stabilizing pressure relief valve and a host of other critical design features (i.e. protective weatherproof casing), every hydraulic power pack we manufacture ensures a clean run, even during busy hours of heavy use.

Non-skid runways

Our runways are roughly textured to ensure your vehicle won’t roll back and forth once you park it. Vehicles remain perfectly still during rise and descent, and they roll off damage-free when the job is done.

Flexible protective conduit

To keep all cables safe from wear, and to prevent accidental shocks, protective tubing wraps around all BendPak four-post lift cables and airlines. The layered conduit is non-conducive to electricity and durable enough to withstand heavy use in busy commercial shops.

Rolling bridge jacks

Wheel service on full-size trucks and commercial vehicles can be tricky without the right equipment. BendPak offers a variety of rolling bridge jacks to support virtually every vehicle type. Hydraulic pumps come standard with each bridge jack, along with SUV/truck adapters you’re going to need in order to reach deeper undercarriages. Never skimp on quality when it comes to heavy-duty lifting (or any lifting, for that matter). Talk to a BendPak service representative to make sure your investment is well-equipped to handle everything your customers might throw your way.

Choose extended length

40,000 lbs. take a lot of muscle to lift, and many vehicles of this caliber are longer than our standard-length series of four-post lifts can accommodate. If you want to be prepared for the longest and heaviest, you need the biggest and baddest. At a whopping 323”, the HDS40X is the heaviest-duty extended-length car lift we make. Slap a bus on it and get to work, no sweat.

Features

- 40,000-lb. lifting capacity

- Supersized 12" diameter cable sheaves

- Stainless steel lifting cables

- Grease nipples

- Single hydraulic under-runway cylinder

- Integrated flow restrictor

- Durable powder coat

- Spring-loaded safety locks

- Second lock system on constant guard

- Fully enclosed lifting cables

- Multiple adjustable height locking positions

- Maintenance-free electric hydraulic power system

- Conveniently positioned operator controls

- 12" x 12" base plates

- Non-skid runways

- Optional rolling jacks

Capacity

Lifting Capacity* 40,000 lbs. (18,144 kg)

*Max Capacity / Front Axle 20,000 lbs. (9,072 kg)

*Max Capacity / Rear Axle 20,000 lbs. (9,072 kg)

Rise

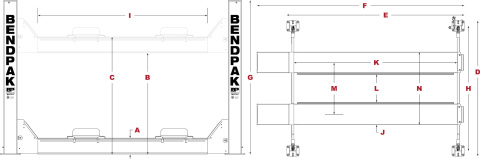

A - Min. Runway Height: 8.5" (216 mm)

B - Max. Rise: 60" (1,524 mm)

C - Max. Lifting Height: 68.5" (1,740 mm)

Time to Full Rise: 75 seconds

Outside Dimensions

D - Overall Width: 154" (3,912 mm)

E - Outside Length: 257" (6,528 mm)

F - Overall Length: 297" (7,544 mm)

G - Height of Columns:93" (2,362 mm)

Inside Dimensions

H - Width Between Columns: 134" (3,404 mm)

I - Drive-Thru Clearance: 109" (2,769 mm)

Runways

J - Runway Width: 28" (711 mm)

K - Length of Runways: 263" (6,680 mm)

L - Width Between Runways: 36" (914 mm) or 47" (1,194 mm)

M - Runway Centerline: 64" (1,626 mm) or 75" (1,905 mm)

N - Outside Edge of Runways: 92" (2,337 mm) or 103" (2,616 mm)

Minimum Wheelbase

Rated Capacity: 185" (4,699 mm)

75% Capacity: 160" (4,064 mm)

50% Capacity: 135" (3,429 mm)

25% Capacity: 110" (2,794 mm)

Locking

Locking Positions: 9

Lock Spacing: Every 6" / 152 mm

Power Unit

Motor: 220 VAC / 60 Hz. 1Ph.

Noise: 45 dB

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201

-

Description

-

features and Specs

Looking for even more lifting capabilities? Check out the extended capacity HDS-40X.

All HDS-40 standard length truck lifts feature:

Spring-loaded safety locks automatically engage continuously during rise and adjustable safety ladders allow for precise runway leveling even when installed on sloped floors.

Supersized 12” diameter cable sheaves within the runway and cross tubes combined with massive 4” diameter sheave axles dramatically improve cable wear and critical component lifespan meaning you’ll increase safety and spend less money in service related expenses down the road.

BendPak's HDS-Truck Series lifts feature four stainless-steel lifting cables that provide a great balance between abrasion resistance and fatigue.

Grease nipples are located on every sheave and sheave axle to make lubrication maintenance a breeze.

Each HDS-Truck Series four-post lift is equipped with a single hydraulic cylinder hidden away under the runway for maximum performance and reliability and minimum exposure to elements. The hydraulic cylinder features high-durometer rod seals, pressure loaded U-cup piston seals, backups and wear bands that virtually eliminate any fluid bypass. The welded cylinder body is made from high strength steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures straight, smooth, cylinders that will provide years and years of dependable trouble-free service. Leak proof cylinder technology only available for BendPak four-post lifts

An integrated hydraulic flow restrictor provides a controlled descent in the unlikely event of an unexpected hose rupture.

A durable powder coat finish can withstand harsh environments and chemical spills and will provide years of protection.

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders will provide years of trouble-free service.

A secondary lock system is on constant guard and acts as a slack-cable device in the unlikely event of an unexpected cable failure.

Lifting cables, airlines, safety latches and sheaves are all fully enclosed within lift structure.

Features multiple adjustable height locking positions for variable-height parking and infinite leveling.

A maintenance-free electric hydraulic power system assures ultimate dependability.

All operator controls are conveniently located within easy reach.

12" x 12" base plates provide a solid foundation.

Non-skid runways provides maximum grip, even when the runway surface is wet or oily.

Optional rolling jacks make a great addition to increase service capacity. Rolling jacks are used to raise the front or rear portion of a vehicle off the runways allowing operators to perform efficient wheel and break service. A pair of jacks allows the entire vehicle to elevated. Each jack has telescoping arms and frame contact pads that can be extended over the runways and positioned under vehicle lifting points. Each jack features three safety-lock positions and stackable truck and van adapters for increased lifting height and better access to frame contact points on high ground-clearance vehicles. The jacks come equipped with a commercial grade air-hydraulic pump.

- 40,000-lb. lifting capacity

- Supersized 12" diameter cable sheaves

- Stainless steal lifting cables

- Grease nipples

- Single hydraulic under-runway cylinder

- Integrated flow restrictor

- Durable powder coat

- Spring-loaded safety locks

- Second lock system on constant guard

- Fully enclosed lifting cables

- Multiple adjustable height locking positions

- Maintenance-free electric hydraulic power system

- Conveniently positioned operator controls

- 12" x 12" base plates

- Non-skid runways

- Optional rolling jacks

*Max capacity / front axle: 20,000 lbs. / 9,072 kg

*Max capacity / rear axle: 20,000 lbs. / 9,072 kg

Overall width: 154" / 3,912 mm

Outside length: 257" / 6,528 mm

Overall length: 297" / 7,544 mm

Height of columns: 93" / 2,362 mm

Runway min height: 8-1/2" / 216 mm

Max rise: 60" / 1,524 mm

Max lifting height: 68-1/2" / 1,740 mm

Width between posts: 134" / 3,404 mm

Runway width: 28" / 711 mm

Width between runways: 36" – 47" / 914 mm – 1,194 mm

Runway centerline: 64" - 75" / 1,625 mm to 1,905 mm

Outside edge of runways: 92" - 103" / 2,367 mm - 2,616 mm

Drive-thru clearance: 109" / 2,769 mm

Length of runways: 263" / 6,680 mm

Min wheelbase @ rated capacity: 185" / 4,699 mm

Min wheelbase @ 75% capacity: 160" / 4,064 mm

Min wheelbase @ 50% capacity: 135" / 3,429 mm

Min wheelbase @ 25% capacity: 110" / 2,794 mm

Locking positions: 9

Lock spacing: every 6" / 152 mm

Lifting time: 75 sec

Motor: 220 VAC / 60 Hz / 1 Ph