- BendPak

- >

- BendPak HD-9SW Double-Wide Car Storage Parking Lift 9,000 lb. - New Gray

BendPak HD-9SW Double-Wide Car Storage Parking Lift 9,000 lb. - New Gray

The super-wide HD-9SW is a parking lift that stores two vehicles side-by-side. With 192” between the posts, this parking lift is wide enough to clear two vehicles underneath and two on the ramps above.

To accommodate super-wide vehicles on a 9,000-lb. capacity four-post lift, choose the HD-9SW. The “SW” stands for super-wide, and it’s the ideal four-post lift to double your parking and/or service wider vehicles.

Take Home a Super-Wide Four-Post Lift

There are thousands of vehicle types out there, and some come a bit wider than others. That’s no sweat for the HD-9SW, a four-post lift that sits fat and happy when it holds vehicles with wider frames. Plus, if you need a lift that offers truly gigantic proportions, the HD-9SWX is one heck of a choice. If your vehicles are tall, heavy and wide, and they need to be stacked or serviced, we can probably lift them. Both models are perfect for a “wide” range of vehicles.

With all the same great parts and components as the HD-9, our super-wide lift is equally safe and efficient. Check out the working parts and components below to see what makes a BendPak better than the rest, no matter what height/width modifications we make for your pleasure and convenience.

Dual-hub cable sheaves

Single-hub cable sheaves represent the cost-cutting way to make a car lift. Not our way. BendPak double-hub sheaves reduce friction against the cables while also extending the life of the lift axles.

Multi-level locking positions

Multiple lock positions permit operators to safely stop the lift at the right height for them, or simply adjust to the right height for the job. This is also useful for parking vehicles under the raised lift. Depending on the height of your vehicle(s), and depending on your ceiling height, you can adjust the lock position.

Heavy-duty aircraft cable

Four lifting cables help ensure a level rise. Each is constructed from high-grade stainless steel and rated to handle 14,000 lbs. Combined, the four cables can hold 640% more than this four post lift’s rated capacity. Of course, the cables are tucked away into the lift structure. This streamlines the lift design and maintains the sleek look of your shop. It also protects the cables from environmental damage, spills, etc.

Electric-hydraulic power system

The electric-hydraulic power system is totally maintenance-free. Controls are ergonomically placed and easy to use, so you’re totally at ease while operating the lift.

Large base plates

10" x 12" base plates can be bolted down or left unbolted for use with the caster kit. We encourage you to work in a way that’s best for you.

Caster kit

A 4-piece caster kit fits this super-wide four-post lift like a charm. With your lift on wheels, there’s no limit to where you can work and park. Remodeling projects are also easier to plan and execute.

Integrated design

All moving components are located within the structure. This isn’t just about looks (although it certainly helps with that too). The integrated design addresses a major safety concern: externally routed components are exposed to additional dangers and damages. BendPak avoids these altogether.

Low-deck runways

The runways on this BendPak four-post lift rise just 4.5" off the ground. Add the gently inclining ramps, and you can lift virtually anything.

Longer approach ramps

Not only are our runways low-profile, we extend them farther than others in the industry. This makes for a car lift that can load sports cars and other low-standing vehicles without damaging them.

Automatic safety locks

Engaging the locks is as simple as raising the ramps just past the lock (you’ll hear it click as it passes) and lowering them back on the lock. Check to make sure all locks are on the same position—safety first, after all. And that’s all there is to it! Your four-post lift can be held in that position indefinitely.

*Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2011 or ANSI/UL 201. Consult www.autolift.org .

Features

- Standard rise

- Shorter runway for smaller spaces

- Runways accommodate wide or narrow vehicles

- Runways include rail kit for optional accessories

- Electric / hydraulic power system

- Single hydraulic cylinder mounted underneath runway

- Fully enclosed lifting cables, safety locks and sheaves

- Internal anti-sway slider blocks in each column

- Oversized self-lubricating cable rollers

- Oversized sheave diameter reduces cable fatigue

- High-speed lifting

- Features heavy-duty 3/8" aircraft cable

- Rugged 1.25" roller axles

- Multi-position safety locks in each column

- Adjustable lock ladders

- Runways feature non-skid surface

- Push-button pneumatic safety release

- Independent backup slack-cable safety latches

- Inside runways adjust for different tread widths

- Customizable power unit location

- Removable approach ramps for additional drive-under clearance

- Optional drive-thru ramps available

- Optional drip trays available

- Optional solid deck available to increase storage capacity

- Optional 4,500-lb. air / hydraulic rolling jacks available

Capacity

Lifting Capacity*9,000 lbs. (4,082 kg)

*Max Capacity / Front Axle4,500 lbs. (2,041 kg)

*Max Capacity / Rear Axle4,500 lbs. (2,041 kg)

Rise

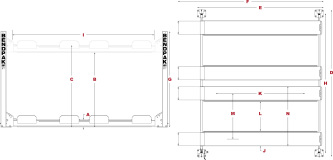

A - Min. Runway Height:7" (178 mm)

B - Max. Rise:70" (1,778 mm)

C - Max. Lifting Height:77" (1,956 mm)

Time to Full Rise:55 seconds

Outside Dimensions

D - Overall Width:202" (5,131 mm)

E - Outside Length:174" (4,420 mm)

F - Overall Length:200" (5,080 mm)

G - Height of Columns:90" (2,286 mm)

Inside Dimensions

H - Width Between Columns:192" (4,877 mm)

I - Drive-Thru Clearance:178" (4,521 mm)

Runways

J - Runway Width:19" (483 mm)

K - Length of Runways:164" (4,166 mm)

L - Width Between Runways:37" (940 mm) or 42" (1,067 mm)

M - Runway Centerline:56" (1,422 mm) or 61" (1,549 mm)

N - Outside Edge of Runways:75" (1,905 mm) or 80" (2,032 mm)

Minimum Wheelbase

Rated Capacity:115" (2,921 mm)

75% Capacity:100" (2,540 mm)

50% Capacity:85" (2,159 mm)

25% Capacity:70" (1,778 mm)

Locking

Locking Positions:14

Lock Spacing:Every 4" (102 mm)

Power Unit

Motor:220 VAC / 60 Hz /1 Ph

Noise:45 dB

Shipping

Weight:2,892 lbs. (1,315 kg)

Dimensions:204" x 24" x 42" (5,182 mm x 610 mm x 1,067 mm)

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201. Consult www.autolift.org for a complete list.

-

Description

-

Features and Specs

The HD-9SW is an industrial-strength 9,000-lb. capacity lift that works equally well in the service shop and at home. The super-wide design allows this lift to raise and store two vehicles simultaneously on four runways, while the shorter ramp design means that the lift fits in tighter shops and garages. When you add in all of the optional kits, this becomes one extremely adaptable four-post. As with all BendPak products, we've engineered the HD-9SW to be tougher and safer than it needs to be. Where other companies might try to get away with the bare minimum, you can always bet on BendPak to find the perfect cross-section of quality, durability and safety.

Double lifter

The unique double-wide design lets you lift and store two vehicles simultaneously. It's like having two lifts, but it takes up much less space.

Grease nipples

Located on every sheave and sheave axle to make lubrication maintenance a breeze.

Dependable design

4 heavy-duty, high-quality, galvanized lifting cables and a single hydraulic cylinder mounted underneath the runway makes this lift the most durable, maintenance-free lifting system on the market.

Dual-hub cable sheaves

Reduce stress and fatigue on the axles, sheaves and cables. We insist on using dual-hub cable sheaves, even if they cost us more to make. When you buy BendPak, we throw in peace of mind free with every lift.

Multi-level locking positions

The HD-9SW is equipped with multiple adjustable height locking positions for variable-height parking. A convenient push-button pneumatic safety lock control releases all four independent safety locks simultaneously.

Heavy-duty aircraft cable

Cables provide a great balance of strength, abrasion resistance and fatigue. Each lift is supplied with 4 high-quality galvanized lifting cables, rated at 14,400 lbs. each. The combined rating of these cables is 640% of the maximum lifting capacity of the entire lift! And we make sure it looks tidy too—all lifting cables are fully enclosed within the lift structure itself.

Electric / hydraulic power system

We incorporate maintenance-free electric hydraulic power systems into each lift for ultimate dependability, and all controls are conveniently located within close reach.

Large base plates

10" x 12" base plates provide a solid foundation for the HD-9SW.

Single hydraulic cylinder

Each lift is equipped with a single hydraulic cylinder, hidden away under the runway for minimum exposure and maximum reliable performance. Our industrial-grade hydraulic cylinders feature a single-piece, pilot fitted, machined steel piston, wrapped with specially designed, pressure loaded U-cup piston seals, backups and wear bands to virtually eliminate fluid bypass. The micro-smooth chrome-rod is machined from high-yield, ground and polished C-1045/50 micro-alloy steel and plated to a minimum of .001" diametrically, to ensure superior cylinder operation and life. The superior-design high durometer, mechanically-loaded rod seals make rod leakage a thing of the past while a specially formulated abrasion-resistant urethane rod wiper provides exclusion protection. The welded cylinder body is made from robust steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures that the cylinders remain straight, smooth and last a very long time. An integrated flow restrictor provides a controlled descent in the case of an unexpected hose rupture.

Durable powder-coat finish

All HD-Series lifts feature a durable powder-coat finish that gives the metal a high-quality, extremely durable finish which can withstand even the harshest environmental or chemical conditions. Unlike other companies that claim to powder coat, we take pride in our meticulous 10-step process. First, all parts are visually inspected before being sandblasted. Afterwards, the parts are washed in our 5-stage phosphate tanks that can accommodate parts up to 25' long. Once cleaned, they're immediately dried to avoid rust production, and then outgassed. Outgassing pre-bakes the parts in a curing oven, reducing the possibility of blemishes that may be hiding in the pores of the metal. If not properly outgassed, imperfections in the metal may bubble during the curing process and most likely will cause chips in the powder. After the parts are washed and outgassed, any surfaces and / or threaded holes that need to be masked or plugged, are done so with high-temperature masking tape and silicone plugs. Next, the parts are given a quick thinner wipe to remove any light debris or fingerprints, before being hung on an electrostatically grounded conveyor line. The powder is finally applied using an electrostatic spray gun. The powder “sticks" to the surface in a fashion similar to how dust sticks to a television screen. Once the parts are powder coated, the carts are rolled into our curing oven and baked at 400° F for 45 minutes.

Integrated design

Lifting cables, airlines, safety latches and sheaves are all fully enclosed.

Low-deck runways

Our low 4-1/2" runways accommodate even the lowest cars.

Longer approach ramps

These approach ramps were designed a little longer to help when loading low ground clearance vehicles. It's the little bit that makes a big difference.

Spring-loaded automatic safety locks

Aircraft-quality stainless steel and aluminum pneumatic cylinders release all 4 locks simultaneously with the simple push of a button. The spring-loaded safety locks automatically engage continuously as the lift is raised. For added safety, a secondary lock system acts as a slack-cable device to engage in the unlikely event of cable failure.

Shorter runway for smaller spaces

Runways accommodate wide or narrow vehicles

Runways include rail-kit for optional accessories

Electric / hydraulic power system

Single hydraulic cylinder mounted underneath runway

Fully enclosed lifting cables, safety locks and sheaves

Internal anti-sway slider blocks in each column

Oversized self-lubricating cable rollers

Oversized sheave diameter reduces cable fatigue

High-speed lifting

Features heavy-duty 3/8" aircraft cable

Rugged 1-1/4" roller axles

Multi-position safety locks in each column

Adjustable lock ladders

Runways feature non-skid surface

Push-button pneumatic safety release

Independent backup slack-cable safety latches

Inside runways adjust for different tread widths

Customizable power unit location

Removable approach ramps for additional drive-under clearance

Optional Adjustable Limit Microswitch

Optional drive-thru ramps available

Optional drip trays available

Optional solid deck available to increase storage capacity

Optional 4,500-lb. air / hydraulic rolling jacks available

*Max capacity / front axle: 4,500 lbs. / 2,041 kg

*Max capacity / rear axle: 4,500 lbs. / 2,041 kg

Overall width: 202" / 5,131 mm

Outside length: 174" / 4,420 mm

Overall length: 200" / 5,080 mm

Height of columns: 88" / 2,235 mm

Runway min height: 7" / 178 mm

Max rise: 70" / 1,778 mm

Max lifting height: 77" / 1,956 mm

Width between posts: 192" / 4,877 mm

Runway width: 19" / 483 mm

Width between runways: 37" – 42" / 940 mm – 1,067 mm

Length of runways: 164" / 4,166 mm

Min wheelbase @ rated capacity: 115" / 2,921 mm

Min wheelbase @ 75% capacity: 100" / 2,540 mm

Min wheelbase @ 50% capacity: 85" / 2,159 mm

Min wheelbase @ 25% capacity: 70" / 1,778 mm

Outside column spacing: 15-1/2" / 394 mm

Locking positions: 12

Lock spacing: every 4" / 102 mm

Lifting time: 55 sec

Motor: 220 VAC / 60 Hz / 1 Ph

Shipping weight: 2,892 lbs. / 1,315 kg

Shipping dimensions: 204" x 24" x 42" / 5,182 mm x 610 mm x 1,067 mm